Page 167 - Proceeding The 2nd International Seminar of Science and Technology : Accelerating Sustainable Innovation Towards Society 5.0

P. 167

nd

The 2 International Seminar of Science and Technology

“Accelerating Sustainable innovation towards Society 5.0”

ISST 2022 FST UT 2022

Universitas Terbuka

substitute for wheat flour [5]. Making mocaf flour is simpler than

making chips because it uses a mocaf flour processing machine.

Fresh cassava is peeled and washed, then chopped with a chopper

machine. After that, the chopped cassava was rewashed before

fermented using a BIMO-CF (Biologically Modified Cassava Flour)

starter with one gram of starter per liter of water. Fermentation is

carried out for 12 hours, then washed and dried in the sun for 2-3 days

on para-para waring or tarpaulin. After drying, the cassava sieve is

pressed, ground into flour using a machine, and packed in a plastic

container. Every production of 1 kg of mocaf flour takes 3 kg of fresh

cassava. The analysis of mocaf flour processing business is shown in

Table. 4.

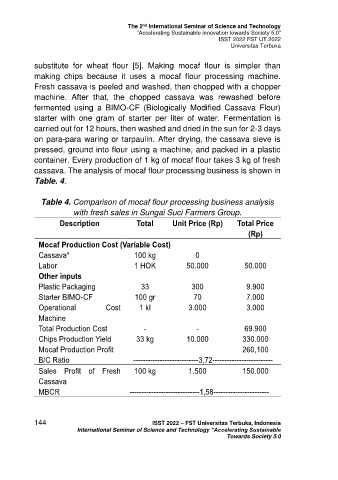

Table 4. Comparison of mocaf flour processing business analysis

with fresh sales in Sungai Suci Farmers Group.

Description Total Unit Price (Rp) Total Price

(Rp)

Mocaf Production Cost (Variable Cost)

Cassava* 100 kg 0

Labor 1 HOK 50.000 50.000

Other inputs

Plastic Packaging 33 300 9.900

Starter BIMO-CF 100 gr 70 7.000

Operational Cost 1 kl 3.000 3.000

Machine

Total Production Cost - - 69.900

Chips Production Yield 33 kg 10.000 330.000

Mocaf Production Profit 260,100

B/C Ratio ---------------------------3,72-------------------------

Sales Profit of Fresh 100 kg 1.500 150.000

Cassava

MBCR -----------------------------1,58-----------------------

144 ISST 2022 – FST Universitas Terbuka, Indonesia

International Seminar of Science and Technology “Accelerating Sustainable

Towards Society 5.0