Page 165 - Proceeding The 2nd International Seminar of Science and Technology : Accelerating Sustainable Innovation Towards Society 5.0

P. 165

nd

The 2 International Seminar of Science and Technology

“Accelerating Sustainable innovation towards Society 5.0”

ISST 2022 FST UT 2022

Universitas Terbuka

using a kitchen knife (modified by the farmer) manually and dried in

the sun for one day on a parachute covered with plastic waring or

tarpaulin. The chips are then put in sacks and stored in a clean and

shady place before being sold to collectors who come to the village.

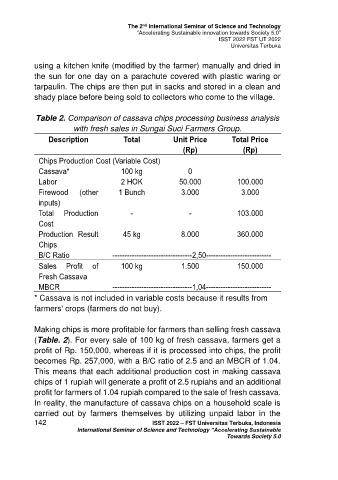

Table 2. Comparison of cassava chips processing business analysis

with fresh sales in Sungai Suci Farmers Group.

Description Total Unit Price Total Price

(Rp) (Rp)

Chips Production Cost (Variable Cost)

Cassava* 100 kg 0

Labor 2 HOK 50.000 100.000

Firewood (other 1 Bunch 3.000 3.000

inputs)

Total Production - - 103.000

Cost

Production Result 45 kg 8.000 360.000

Chips

B/C Ratio ---------------------------------2,50---------------------------

Sales Profit of 100 kg 1.500 150.000

Fresh Cassava

MBCR ---------------------------------1,04---------------------------

* Cassava is not included in variable costs because it results from

farmers' crops (farmers do not buy).

Making chips is more profitable for farmers than selling fresh cassava

(Table. 2). For every sale of 100 kg of fresh cassava, farmers get a

profit of Rp. 150,000, whereas if it is processed into chips, the profit

becomes Rp. 257,000, with a B/C ratio of 2.5 and an MBCR of 1.04.

This means that each additional production cost in making cassava

chips of 1 rupiah will generate a profit of 2.5 rupiahs and an additional

profit for farmers of 1.04 rupiah compared to the sale of fresh cassava.

In reality, the manufacture of cassava chips on a household scale is

carried out by farmers themselves by utilizing unpaid labor in the

142 ISST 2022 – FST Universitas Terbuka, Indonesia

International Seminar of Science and Technology “Accelerating Sustainable

Towards Society 5.0