Page 164 - Proceeding The 2nd International Seminar of Science and Technology : Accelerating Sustainable Innovation Towards Society 5.0

P. 164

nd

The 2 International Seminar of Science and Technology

“Accelerating Sustainable innovation towards Society 5.0”

ISST 2022 FST UT 2022

Universitas Terbuka

Harvest

cassava

Fresh sweet Fresh

cassava sales processing

Leather Chips raw material Mocaf raw material

waste

Animal feed and solid Mocaf rengginang

fertilizer raw material

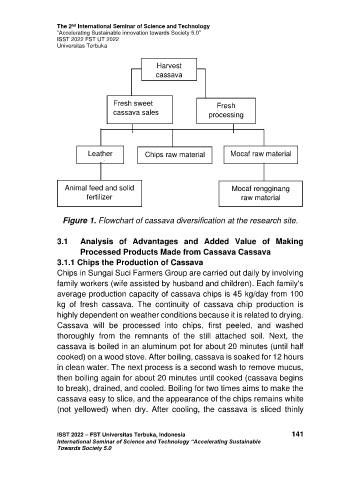

Figure 1. Flowchart of cassava diversification at the research site.

3.1 Analysis of Advantages and Added Value of Making

Processed Products Made from Cassava Cassava

3.1.1 Chips the Production of Cassava

Chips in Sungai Suci Farmers Group are carried out daily by involving

family workers (wife assisted by husband and children). Each family's

average production capacity of cassava chips is 45 kg/day from 100

kg of fresh cassava. The continuity of cassava chip production is

highly dependent on weather conditions because it is related to drying.

Cassava will be processed into chips, first peeled, and washed

thoroughly from the remnants of the still attached soil. Next, the

cassava is boiled in an aluminum pot for about 20 minutes (until half

cooked) on a wood stove. After boiling, cassava is soaked for 12 hours

in clean water. The next process is a second wash to remove mucus,

then boiling again for about 20 minutes until cooked (cassava begins

to break), drained, and cooled. Boiling for two times aims to make the

cassava easy to slice, and the appearance of the chips remains white

(not yellowed) when dry. After cooling, the cassava is sliced thinly

ISST 2022 – FST Universitas Terbuka, Indonesia 141

International Seminar of Science and Technology “Accelerating Sustainable

Towards Society 5.0